Introduction

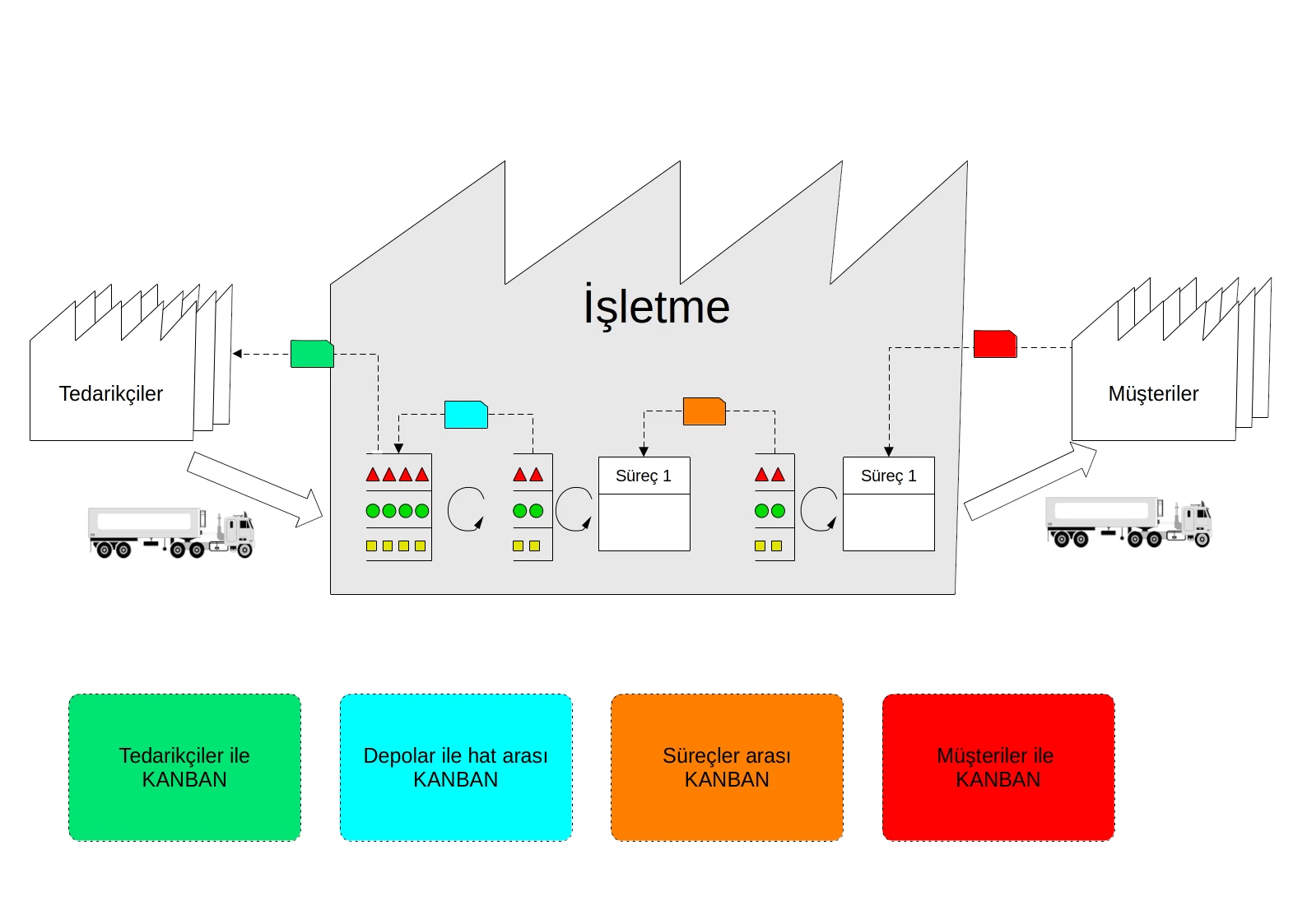

One of the important elements of the lean production system is the pull system. The main thing here is to produce and replace the consumed product or semi-finished product. Thus, increasing stocks and unnecessary production is prevented. At the same time, a significant reduction in delivery time is achieved. The Kanban system is a system developed by the great sensei Taiichi Ohno. The system, in which the supply / production signal is given by kanban cards, has now become operational with an electronic signal and has transformed from an inter-process kanban application to an inter-country kanban application. Many international companies implement electronic kanban among their suppliers, customers and locations.

- Performing the necessary analyzes of the kanban system, calculating kanban quantities,

- Making the necessary infrastructure changes to establish and maintain the Kanban system,

- Reducing stocks, as well as eliminating downtime due to lack of materials,

- Shortening the customer delivery time, same-day delivery or delivery within the specified time,

- Increasing the service level (on-time delivery rate) to 98%,

- Elimination of idle stocks,

- Establishing the infrastructure for regular production and transition to a regular supply system

Ho we work?

Project outline

- General information: Contains general information about Kanban applications.

- Scope: The results and implementation method of the kanban and milk-run applications within the scope of the project are briefly explained.

- Project time plan: It is the project plan showing the time required to implement the kanban and pulling system within the scope of the project and the amount of consultancy service to be provided during this period in man-days.

- Pricing: Information about the man-day unit price, the monthly invoice amount and the total project cost.

- Contact and general information about our consultants who may take part in the project and our references